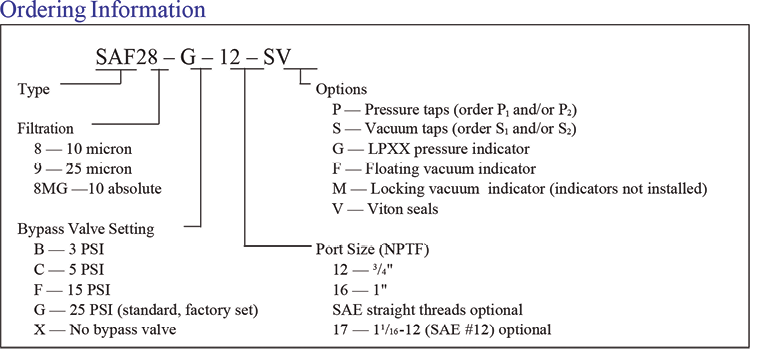

Spin On Filters

Spin On Single Filters

Series SAF20

SPECIFICATIONS

Operating Pressure: 175 PSI (12.06 Bar) maximum

Operating Temperature: 250° F (121° C) maximum

Standard Seals: Buna-N

Element Area: 450 in.2 (2903 cm2)

Beta Rating-10 micron elements B10=2.2 B20=Greater than 100Beta Rating-25 micron element B30=4Beta Rating- 10 micron glass B12=100

FEATURES

- Inexpensive.

- Easy maintenance.

- Only 3/4″ removal clearance needed for replacing cartridge.

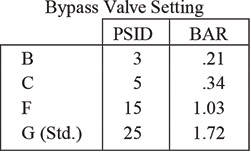

- Bypass valve with wide choice of settings.

- Rugged die cast aluminum head.

- Optional 1/4″ + 1/8″ NPTF gauge ports with 1/8 NPTF to 1/4 NPTF Adapter

APPLICATIONS

Designed for most return line applications up to 20 GPM (76 L/min.). Also can be used for lower flow suction line applications. Compatible with petroleum-based oil in mobile and industrial equipment.

OPERATION

Dirty fluid enters the inlet port and permeates the filtering medium, causing contaminants to be trapped on its outer surface. Clean fluid is then directed through the outlet port. An optional integral bypass valve can be used to protect the element against line surges and high differential pressure due to contamination.

Optional 1/4/”-1/8″ NPTF Gauge Ports Either Side

*Consult Factory Loxx Indicator 4

Spin On Single Filters

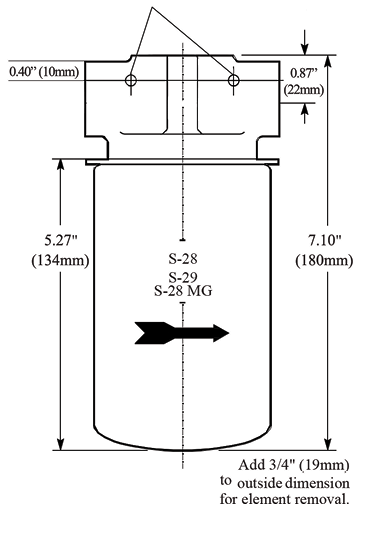

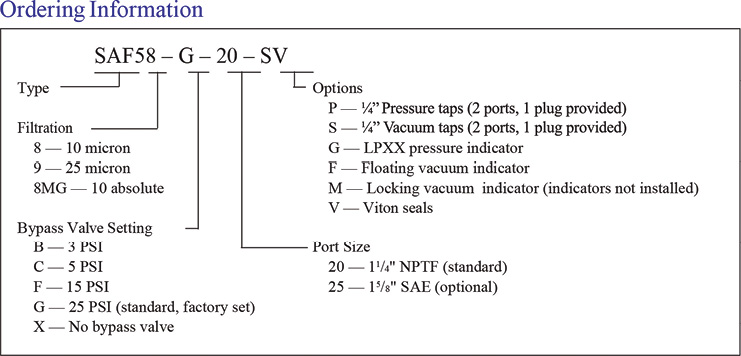

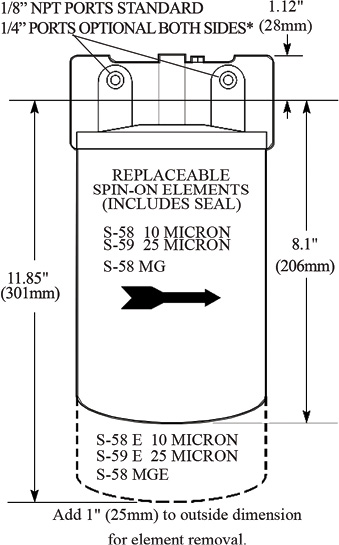

Series SAF50

SPECIFICATIONS

Operating Pressure:100 PSI (6.89 Bar) maximum

Operating Temperature:250° F (121° C) maximum

Standard Seals: Buna-N

Element Area: 950 in.2 (6129 cm2)

Filter Retention: 10 micron nominal 33 micron absolute B10=1.5 25 micron nominal 67 micron absolute B30=4 10 micron glass B12=100

FEATURES

- Inexpensive and easy to maintain.

- Extended element available for higher flows at lower P.

- Only 3/4″ removal clearance needed for replacing cartridge.

- Bypass valve with wide choice of settings.

- Rugged die cast aluminum head.

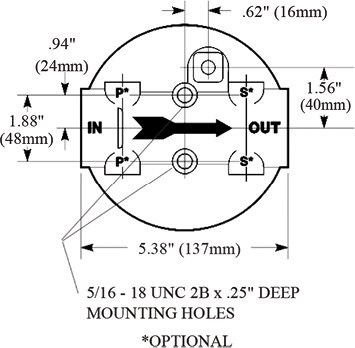

- Optional 1/4″ NPTF gauge ports.

APPLICATIONS

Designed for most return line applications up to 50 GPM (189 L/min.). Also can be used for lower flow suction line applications.

Compatible with petroleum-based oil in mobile and industrial equipment.

OPERATION

Dirty fluid enters the inlet port and permeates the filtering medium, causing contaminants to be trapped on its outer surface. Clean fluid is then directed through the outlet port. An optional integral bypass valve can be used to protect the element against line surges and high differential pressure due to contamination.

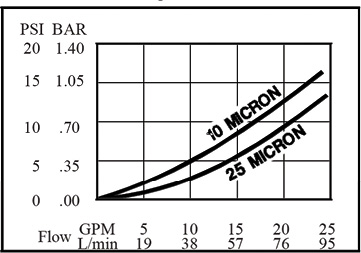

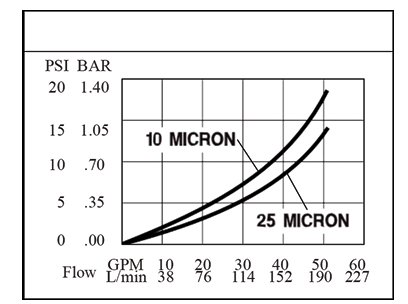

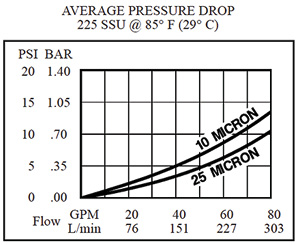

AVERAGE PRESSURE DROP 225 SSD @ 85°F (29°C)

*Consult Factory LDxx Indicator 4

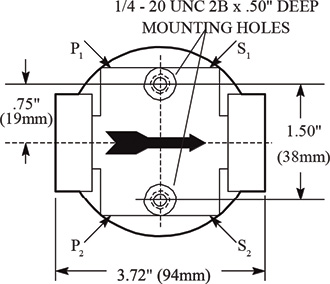

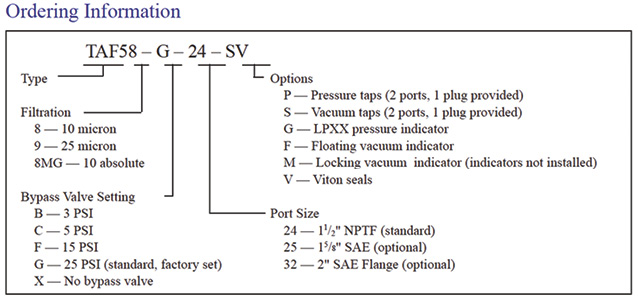

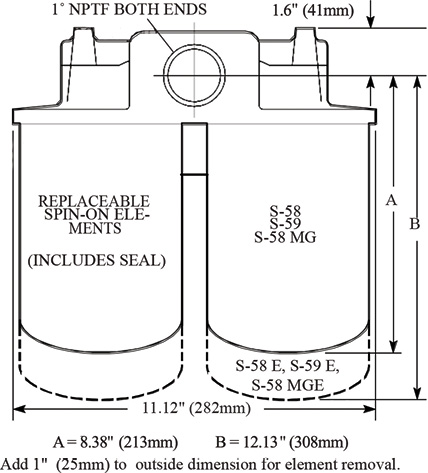

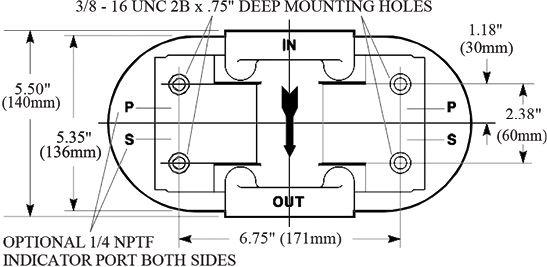

Spin On Twin Filters

Series TAF50

OPERATION

Dirty fluid enters the inlet port and permeates the filtering medium, causing contaminants to be trapped on its outer surface. Clean fluids are then directed through the outlet port. An optional integral bypass valve can be used to protect the element against line surges and high differential pressure due to contamination.

FEATURES

- Inexpensive and easy to maintain

- Only 1″ removal clearance needed for replacing cartridge.

- Bypass valve with wide choice of settings

- Rugged die cast aluminum head.

- Optional 1/4″ NPTF gauge ports

- Double dirt holding capacity.

APPLICATIONS

Designed for most return line applications up to 80 GPM (303 L/min.). Also can be used for lower flow suction line applications. Compatible with petroleum-based oil in mobile and industrial equipment.

SPECIFICATIONS

Operating Pressure: 100 PSI (6.89 Bar) max.

Operating Temperature: 250°F (121°C) max.

Standard Seals: Buna-N

Element Area: 1900 in.2 (12,259 cm2)

Filter Retention: 10 micron nominal 33 micron absolute B10=1.5 25 micron nominal 67 micron absolute B30=4 10 micron glass B12=100 spin on elements micro glass

*Consult Factory LDxx Indicator 4

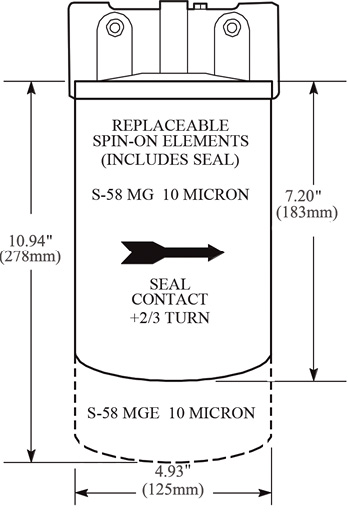

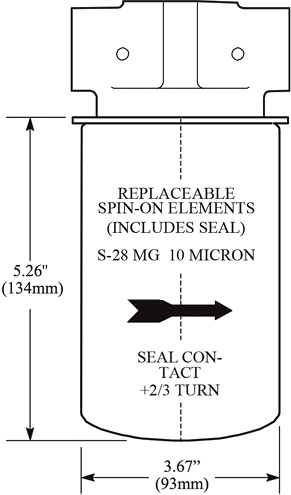

Spin On Elements Micro Glass

Series S-20 MG

FEATURES/BENEFITS

- Much lower pressure drop

- Improved efficiencies

- Higher dirt holding capacity

- Better performance at low temperatures with high viscosity fluids

- Long term cost effectiveness

APPLICATIONS

- Petroleum fluids REPLACEABLE

- Water/oil emulsions SPIN-ON ELEMENTS

- HWBF

- Lube oils

OPERATION

Dirty fluid enters the inlet port and permeates the filtering medium, causing contaminants to be trapped on its outer surface. Clean fluid is then directed through the outlet port. An optional integral bypass valve can be used to protect the element against line surges and high differential pressure due to contamination.

SPECIFICATIONS

Micron Rating: B10 = 75

Working Pressure: 175 PSID

Media: Micro Glass

Dirt Holding Capacity: 22 grams

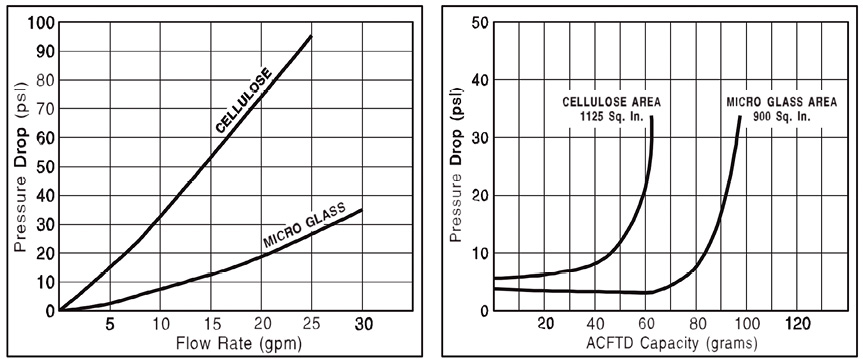

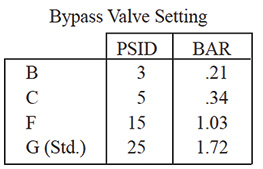

Micro Glass Benefits

REDUCED RESTRICTION

Resistance to Cold Flow

Fluid Viscosity: 2200 SSU

Typical Cellulose and Micro Glass

Hydraulic Media with the same Beta10 Value

DIRT HOLDING CAPACITY

Capacity vs. Restriction

Typical Cellulose and Micro Glass

Hydraulic Media with the same Beta10 Value

Test Flow Rate – 25 gpm

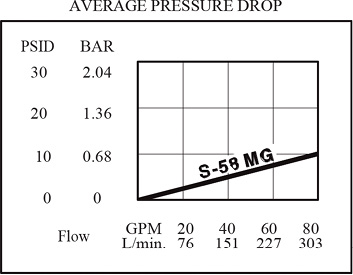

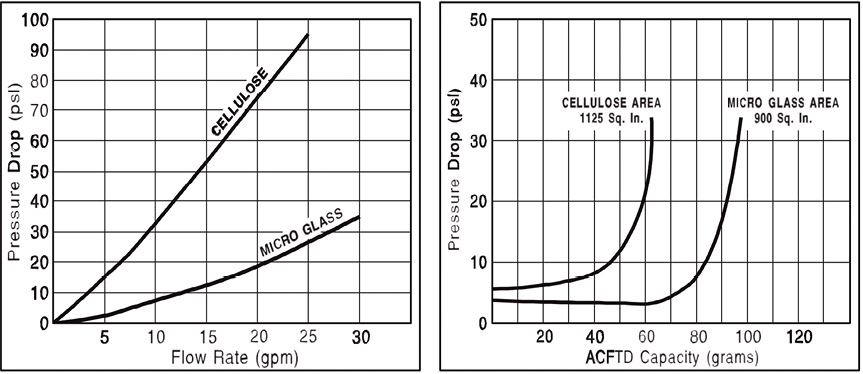

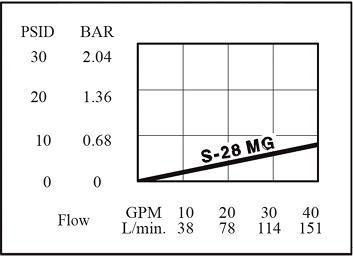

AVERAGE PRESSURE DROP

Spin On Elements Micro Glass

Series S-50 MG

FEATURES/BENEFITS

- Much lower pressure drop

- Improved efficiencies

- Higher dirt holding capacity

- Better performance at low temperatures with high viscosity fluids

- Long term cost effectiveness

APPLICATIONS

- Petroleum fluids

- Water/oil emulsions

- HWBF

- Lube oils

OPERATION

Dirty fluid enters the inlet port and permeates the filtering medium, causing contaminants to be trapped on its outer surface. Clean fluid is then directed through the outlet port. An optional integral bypass valve can be used to protect the element against line surges and high differential pressure due to contamination.

SPECIFICATIONS

Micron Rating: B10 = 75

Working Pressure: 100 PSID

Media: Micro Glass

Dirt Holding Capacity: 43 grams

Micro Glass Benefits

REDUCED RESTRICTION

Resistance to Cold Flow Fluid Viscosity: 2200 SSU

Typical Cellulose and Micro Glass

Hydraulic Media with the same Beta10 Value

DIRT HOLDING CAPACITY

Capacity vs. Restriction

Typical Cellulose and Micro Glass

Hydraulic Media with the same Beta10 Value

Test Flow Rate – 25 gpm